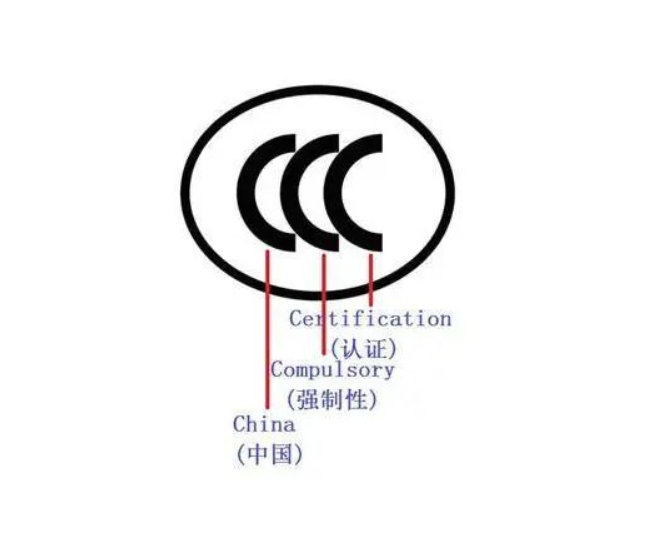

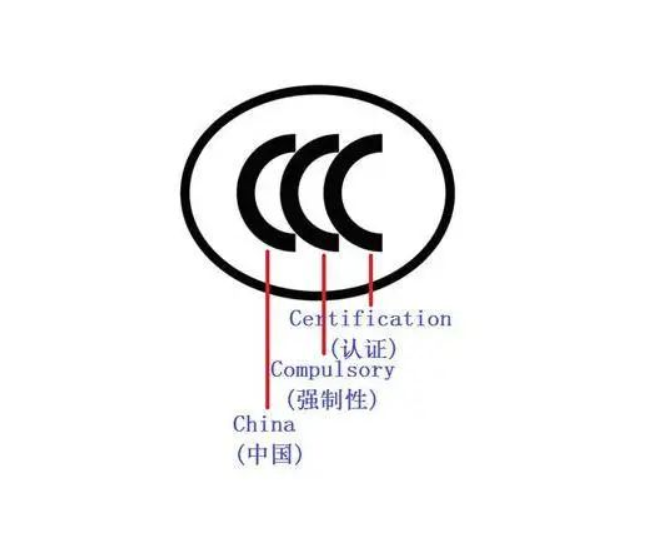

As a core information technology device, monitors have been explicitly included in the "Compulsory Product Certification Catalogue". All monitors (including computer monitors, industrial monitors, etc.) that are manufactured, sold, imported or used for business activities in the Chinese market must pass CCC certification and mark the certification symbol. This is a legal requirement to ensure usage safety and electromagnetic environment.

The core testing of CCC certification for displays focuses on two major dimensions: safety performance and electromagnetic compatibility (EMC). Safety performance testing focuses on risk prevention and control in scenarios where users come into direct contact: including electric shock protection, detecting whether the creepage distance and electrical clearance meet the standards, and avoiding electric leakage injuries. Fire resistance and heat resistance tests are conducted to verify the flame retardant grades of components such as the casing and circuit boards, as well as the temperature resistance performance of the components, to prevent overheating and fire. Mechanical safety tests check the structural strength to prevent physical injuries caused by component detachment or shell rupture.

Electromagnetic compatibility testing is a crucial step in display certification, which is divided into two parts: electromagnetic radiation emission and electromagnetic immunity. The former limits the electromagnetic interference generated by the display during operation to prevent it from affecting the normal operation of peripheral devices such as televisions and radios. The latter ensures that the display can work stably in complex electromagnetic environments (such as mobile phone signals and grid fluctuations), avoiding problems such as screen flickering and system freeze.

The certification process typically consists of four steps: First, submit an application to an accredited body (such as CQC) and provide product technical data; Secondly, send the samples to the designated laboratory to complete the type test and obtain the qualification report. Subsequently, the certification body conducts on-site inspections of the production plant to verify the production consistency capability. Upon passing, a certificate will be issued, and subsequent regular supervision and inspection are required to maintain the validity of the certification.

It should be noted that the scope of CCC certification for displays is not absolute. It needs to be determined in combination with product parameters and applications, and the catalogue will be dynamically adjusted with technological development. Uncertified monitors are not allowed to enter the market. Violators will face administrative penalties. This certification system not only builds a solid safety line for consumers but also regulates the market order, serving as an "essential pass" for displays to enter the Chinese market.