introduction

Since the lithium-ion battery interview, after just four years, he has faced his first crisis: more than 1 million lithium-ion batteries in the Sony County Hill factory caught fire for unknown reasons. Subsequently, it took Sony five months to persuade the Tokyo Fire Department to avoid the "dangerous goods" label on lithium-ion batteries. At the same time, Sony has also conducted a lot of research on the safety performance of lithium-ion batteries, and the safety test standards for lithium-ion batteries have begun to gradually improve.

Making the safest battery is the unremitting pursuit of every one of us. This article will use the thermal runaway principle of lithium-ion batteries as an entry point, focusing on the failure principles and improvement plans of six lithium-ion battery safety tests in order to help everyone's daily work.

Principle of thermal runaway

Why are lithium-ion batteries dangerous? Because a lithium-ion battery integrates all the contents of the three elements of combustion:

High temperature-caused by large rate charge and discharge or internal and external short circuit;

Combustibles-electrolyte, diaphragm, negative electrode, etc.;

Oxygen-most cathodes decompose and generate oxygen at high temperature or high voltage;

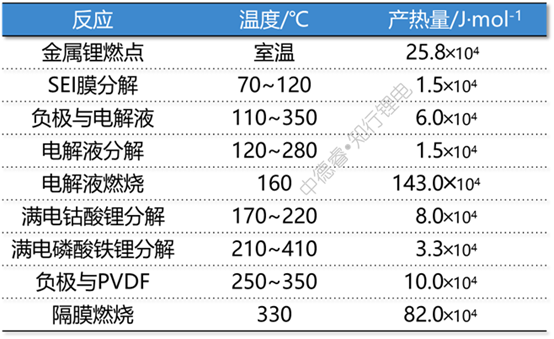

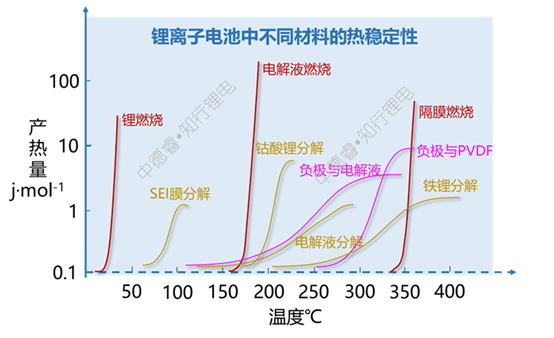

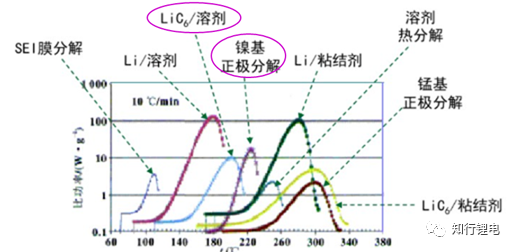

Therefore, in some extreme situations, lithium-ion batteries are prone to thermal runaway and fire explosion. Specifically, the thermal reactions that may occur in lithium-ion batteries are as follows:

As can be seen from the above figure, the side reactions inside the lithium-ion battery cover almost the entire temperature range above 70 ℃. Does that mean that the side reactions in the lithium-ion battery are like a set of dominoes, and the first one is overturned, the follow-up Will it spontaneously carry out the "chain reaction"? The answer is not so, the main reasons are the following:

(1) The mass of some thermal reactions is too small, and the heat production is not enough to further increase the temperature of the cell to the next thermal reaction, such as SEI film decomposition;

(2) The rate of some thermal reactions at a low temperature is too low, and the rate of heat production cannot even catch up with the rate of heat dissipation of the cell, so it is not enough to cause danger, such as the reaction of the negative electrode with the electrolyte;

(3) Lithium is very dangerous, but the premise is that the battery is severely lithium-evolving; burning is terrible, but the premise is that the cathode decomposes to produce oxygen or a large amount of air enters the environment inside the battery. Therefore, it is not that the temperature is reached, the cell will enter thermal runaway.

That is to say, simply studying the safety of the battery cell based on the above thermal reaction still has some feelings according to this text. As Chen Lin, a teacher of Sino-Germany who has many years of consulting experience, said: For the discussion of battery safety, it is best to use the common failure principles of various safety tests as a breakthrough to understand the "failure board" of each test Where, then targeted improvement.

The main content of this article is based on the six common safety tests of lithium-ion batteries (thermal shock, acupuncture, heavy object impact, overcharge, overdischarge, external short circuit), giving priority to its failure principle, and according to the failure principle Analysis of the proposed improvement plan.

Safety principles and improvement

1. Thermal shock

Test Conditions

After the battery is fully charged, the high temperature storage at 130 ℃ (150 ℃) for 10min (30min)

Failure principle

High-temperature storage causes the separator to shrink severely, which causes a short circuit in the large area of the positive and negative electrodes and generates a lot of heat. When the battery temperature exceeds the thermal runaway temperature, it will fire and explode.

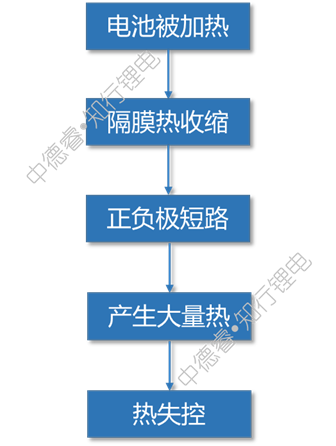

The causal chain diagram describes the failure principle as follows:

Improvement plan

All improvements in this article are strictly based on the analysis of the "causal chain diagram" above.

Next, we will carefully consider the improvement plan of thermal shock based on the above-mentioned causal chain diagram:

Improvement for "battery is heated"

Translating the above content is: can the battery not be heated to such a high temperature during thermal shock?

Although this is not easy to do, Wenwu can still imagine some conceptual methods, such as adding some materials with high specific heat capacity to the battery to slow down the temperature rise inside the battery, or coating a battery box with a A layer of thermal insulation material prevents external heat from being transferred to the battery too quickly.

Of course, the above improvements are not necessarily industrially feasible or of great in-depth research value for our lithium battery people. Wen Wu wrote it, one is to broaden everyone's thinking, and the other is to show the value of causal chain analysis.

Improvement for "diaphragm thermal shrinkage"

How to avoid the thermal shrinkage of the diaphragm under thermal shock conditions is the key point to improve the thermal shock.

The melting point of the PE material diaphragm is about 130°C, and the melting point of the PP material diaphragm is about 160°C. That is to say, if the separator is made of PP or PP/PE composite material, high-temperature storage is not enough to cause the separator to shrink, and it will not cause subsequent short-circuits in the positive and negative electrodes and further heat release, and the battery is safe under thermal shock.

PE material diaphragm melts badly after 130℃ for 30min

PP/PE/PP three-layer membrane changes little after 30 min at 130℃

After the battery has undergone a thermal shock test, you can simply test the voltage to determine whether the separator has melted over a large area. The two groups of batteries that have passed the thermal shock can still maintain the safety of the battery at almost full charge voltage. The battery has become 0V after thermal shock.

For the PE-coated ceramic diaphragm, although the degree of shrinkage is lower than that of the PE substrate, it still cannot withstand the test of 130 ℃ for 30 minutes, so the risk still exists.

Improvement for "Positive and negative short circuit"

Is there a way to prevent the positive and negative electrodes from short-circuiting under the condition that the separator has contracted? As long as the positive and negative poles are not short-circuited, no additional heat will be generated inside the battery, thus avoiding the thermal runaway of the battery.

Under normal circumstances, the separator is the only barrier between the positive and negative electrodes. If the separator is melted and the positive and negative electrodes are not short-circuited, you can only add some other substances between the positive and negative electrodes. For example, you can consider coating PTC on the pole piece. Thermal sensitive material, although the diaphragm is no longer present during thermal shock, the thermal sensitive material can still continue to block the positive and negative short circuits.

Improvement for "Generating a lot of heat"

Expecting a short circuit at 130°C in a large area without generating a lot of heat should be difficult. The possible improvement is to find a way to add a thermal conductive layer in the cell to conduct the heat generated by the short circuit as soon as possible.

Improvement for "thermal runaway"

The battery is short-circuited at 130°C and the temperature is further increased. At this time, the battery needs to be thermally uncontrolled, so naturally a material with good thermal stability is needed. In the above "Theory of Thermal Runaway", Chinese Wu once mentioned that almost all the materials in the cell are unstable at high temperatures, so do you need to change all the materials again?

Although the decomposition temperature of the SEI film and the side reaction temperature of the negative electrode and the electrolyte are relatively low, the speed of the two is also very slow, even if it occurs, it is not enough to cause the thermal runaway of the cell.

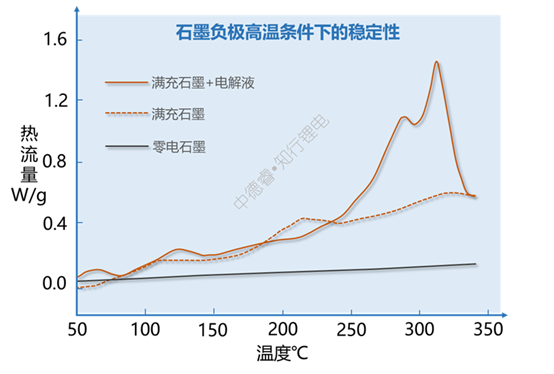

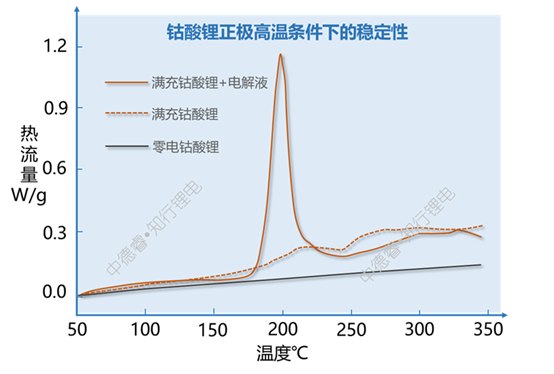

The thermal runaway temperature of the fully charged graphite negative electrode is above 250 °C. Thermal shock + internal short circuit is not enough to cause such a high temperature. Therefore, the negative electrode is not a failure shortcoming of thermal shock. In comparison, the positive electrode is much more dangerous when fully charged:

When the temperature of the fully charged lithium cobaltate + electrolyte exceeds 180°C, the two will react and generate a lot of heat, which will cause the battery to runaway. Therefore, compared with the negative electrode, the improvement of the positive electrode is the short board to avoid the thermal runaway of the battery.

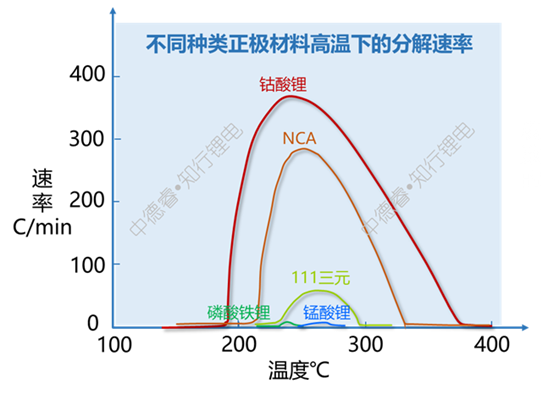

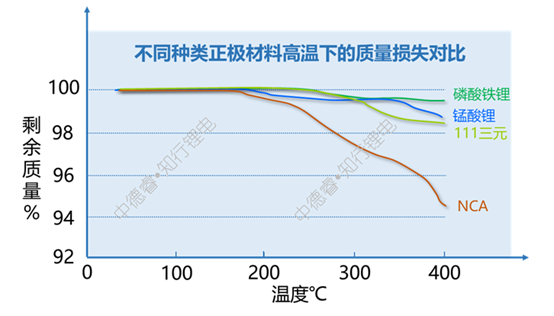

For the positive electrode, its instability is mainly reflected in the decomposition of oxygen production at full charge. The difference in oxygen production of different types of fully charged cathode materials at high temperatures can be shown with the following two figures:

As can be seen from the above two figures, the decomposition temperature of lithium iron phosphate and lithium manganate is relatively high, and the amount of oxygen produced is very small. Therefore, the lithium ion battery used as a positive electrode, regardless of thermal shock or other safety tests, the safety will be A substantial increase.

For high-nickel ternary and lithium cobaltate, it is inevitable to produce a large amount of oxygen at high temperature and full charge. The treatment methods such as coating and reducing the specific surface area may slightly improve the results, but they cannot be fundamentally solved. To improve the safety performance of the material.

In addition, if the boiling point of the electrolyte solvent is low or side reactions are more likely to occur with the positive and negative electrodes, it is easier to flush the battery box during thermal shock, resulting in a large area of contact between the internal environment of the cell and the external oxygen , Which greatly increases the probability of thermal shock failure.

Doubts: Short circuit within 130℃ is not enough to make the battery runaway?

We know from experience: Many times we use PE or PE-coated ceramic diaphragms. At this time, the thermal shock of the battery cell must be shorted internally, but most of the time, thermal shock is a safety test that is not difficult to pass, that is, It is said that the short circuit in the cell at 130 ℃ is not enough to cause thermal runaway. This is contrary to the result that the cell is very vulnerable to thermal runaway after needle sticking (causing a short circuit). Why?

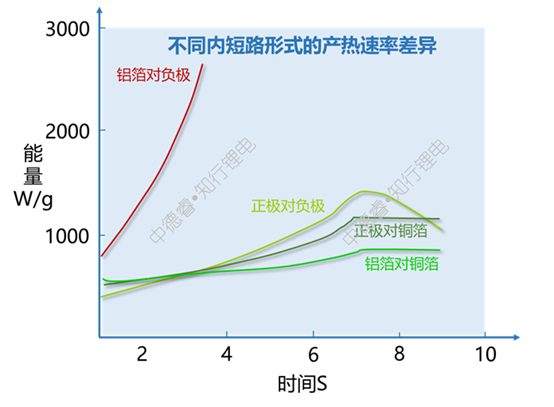

"Internal short circuit" is actually a relatively broad concept. Specifically, there are four types of internal short circuit in the cell, and the various forms of contact resistance are as follows:

If the contact resistance of the short-circuit point is too large, the overall short-circuit current will be relatively small; if the contact resistance of the short-circuit point is too small, although the short-circuit current becomes large, the contact point will not generate much heat due to the small resistance. Generally speaking, the maximum heat is generated when the contact resistance of the short-circuit point is close to the internal resistance of the cell.

For the thermal runaway of the battery, not only the heat generation but also the heat dissipation need to be considered. Although the short circuit in copper foil and aluminum foil is large in current and generates a lot of heat, both are good conductors of heat, and the heat cannot be collected, which is not enough to cause local high temperature and cause thermal runaway. The short circuit between the aluminum foil and the negative electrode is the most dangerous. One of the reasons is that the heat generation is large, and the second is that graphite dissipates heat slowly compared to metal.

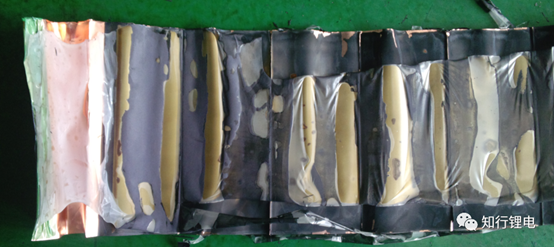

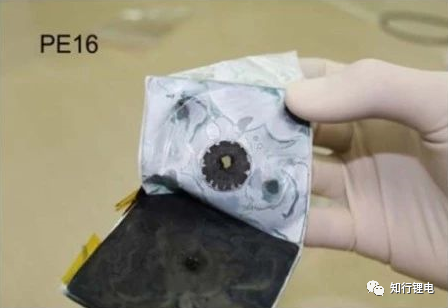

In the thermal shock safety test, the main forms of internal short circuit after the diaphragm is melted are positive electrode to negative electrode, aluminum foil to copper foil, the former has a contact resistance of ohm level, and the current generated is only a few times (the above thermal shock diaphragm melts the battery and disassembles To understand the picture, the negative electrode has a large area of golden yellow, indicating that although an internal short circuit has occurred, but the electricity has not been discharged), the latter generates heat and cannot gather, therefore, the internal short circuit during thermal shock is often not enough to cause electricity Core thermal runaway.

Thermal shock summary

Failure principle: thermal shock causes the diaphragm to shrink and melt, causing a short circuit in the cell

Key improvement points: diaphragm material

Possible improvements: positive electrode stability, electrolyte stability

Brainstorming improvement points: increase the specific heat capacity of the battery core, and coat the surface of the positive and negative electrodes with heat-sensitive materials

2. Acupuncture

Test Conditions

After the battery is fully charged, pierce its body with a steel nail moving at a uniform speed

Failure principle

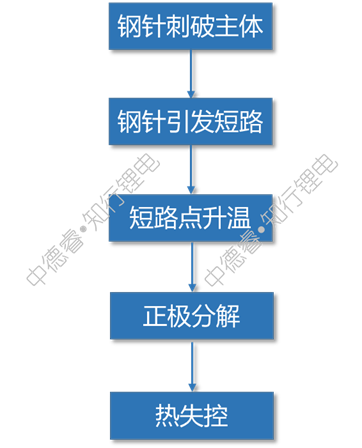

The steel nail punctures the main body of the battery cell, thereby causing a short circuit between the positive electrode and the negative electrode. The short-circuit point is concentrated in a small area punctured by the steel needle, and the generated heat is highly concentrated, thereby causing the thermal runaway of the battery cell.

The causal chain diagram describes the failure principle as follows:

Improvement plan

Improvement for "steel needle piercing the main body"

(This paragraph is purely counted)

Improvement for "steel needle short circuit"

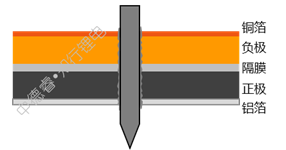

The steel needle punctured the main body of the battery and caused a serious internal short circuit, which can be said to be the root cause of the thermal runaway of the needle. After the steel needle punctured the main body of the battery, the internal schematic diagram is as follows:

At this time, the steel needle must be in contact with the positive and negative electrodes. Since the steel needle is a conductor, it will definitely cause a short circuit of the positive and negative electrodes. Therefore, if the steel needle does not cause a short circuit, it can only be pinned to let the steel needle become an insulator at this time.

Corresponding conceptual solutions exist: a layer of insulation is coated inside the cell casing. When the steel needle pierces the casing, the insulation layer will wrap the steel needle, thus allowing the steel needle to pierce the cell insulation.

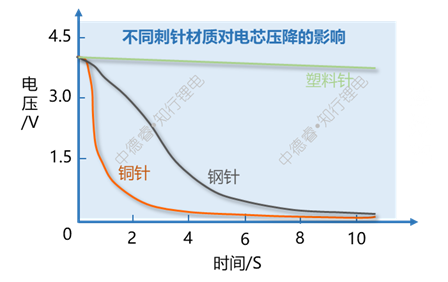

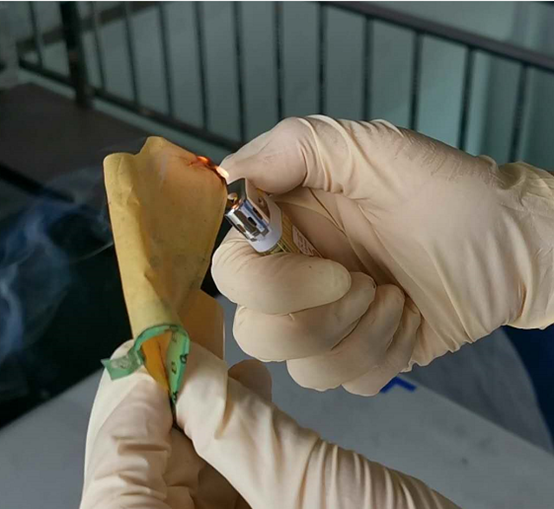

The actual effect of the above improvement is not easy to verify, but after using a plastic needle to pierce the cell, the cell is difficult to fire and explode, but it is easy to verify:

When a plastic needle is used, the voltage of the cell only slowly drops after acupuncture, indicating that the insulation of the lancet can indeed improve the result of acupuncture.

Improvement for "short-circuit temperature rise"

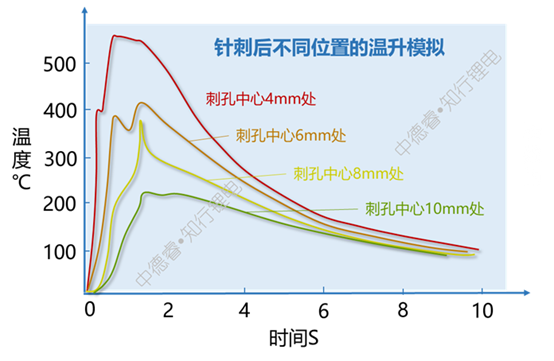

The reason why acupuncture is the most difficult safety test is mainly due to the concentrated high temperature caused by a short circuit at the location of the puncture point. We know from Wen Wu's thermal failure principle mentioned in the previous article: The real thermal runaway chain reaction in the cell is not the mutual heating or reaction transfer between the materials, but the local thermal runaway is easy to cause the overall thermal runaway.

In addition to the local ultra-high temperature, the internal short circuit caused by the puncture needle is also very complicated and dangerous: after the battery core is punctured, the diaphragm is likely to melt over a large area due to overheating:

Copper and aluminum foils are prone to lead after acupuncture, the dressing may also fall off, and the laminated structure of the positive and negative electrodes will also change due to the pressure of the puncture needle:

Therefore, the internal short-circuit state after acupuncture is not as regulated as thermal shock (positive to negative, aluminum to copper), but there may be four situations including aluminum foil to negative electrode, which is undoubtedly very dangerous. It also makes the reproducibility of the acupuncture experiment worse.

We can summarize that the root cause of the temperature rise of the internal short circuit of the needle stick is that a complicated internal short circuit (including between the aluminum foil and the negative electrode) and a large amount of heat accumulate at the puncture point. According to this principle, the following possibilities are solved Program:

(1) Is there any kind of aluminum foil that does not produce burrs when acupuncture? For example, will the aluminum foil with large holes or coated aluminum foil improve the needling?

(2) Is there a way to reduce the short-circuit current between the aluminum foil and the negative electrode short circuit: the first thing that can be thought of is to treat the surface of the aluminum foil to increase the resistance when it contacts the negative electrode;

The second is the familiar vest structure. The vest is directly short-circuited between the aluminum foil and the copper foil. The contact resistance between the two is only 1% between the aluminum foil and the negative electrode. It can shunt the internal short-circuit current to a large extent, which is significant Improve acupuncture.

The use of the negative electrode or copper foil finishing structure may also improve the needling. At this time, the puncture needle will first puncture the negative electrode, which may preferentially cause a short circuit between the copper foil and the positive electrode and disperse the short circuit current.

(3) Is there any way to keep the aluminum foil and the negative electrode from contacting during acupuncture? If the single-layer pole piece can be made so hard that it will not be easily deformed during needle punching, or if the diaphragm has a high strength and melting point, this goal may be achieved.

(4) Is there any way to improve the heat dissipation of the battery cell? The biggest difference between acupuncture and short circuit, thermal shock, etc. is that the huge energy of the battery is instantly released locally during short circuit, and the reason for the release is mainly due to the short circuit of aluminum foil and the negative electrode; therefore, if the thermal conductivity of the negative electrode can be greatly improved, even let Its thermal conductivity is close to that of metal, so the hazard of short circuit between the aluminum foil and the negative electrode is really similar to aluminum foil to copper foil.

As far as the cell level is concerned, the smaller the number of the cell layers, the thinner it is equivalent to reducing the chance of contact between the aluminum foil and the negative electrode after needle punching. Some thin and large lithium cobalt oxide batteries may even directly pass through needle punching.

Improvement for "Positive Cathode Decomposition"

According to the experiment, we know that the lithium iron & lithium manganate cathode with graphite anode is easy to pass through the needle. This also proves that the cathode is the key to the safety of the battery after a short circuit. Similarly, mixing or coating some lithium iron or lithium manganate in ternary and lithium cobaltate may also have a significant improvement effect on acupuncture.

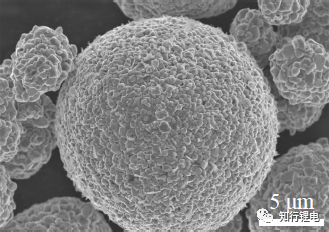

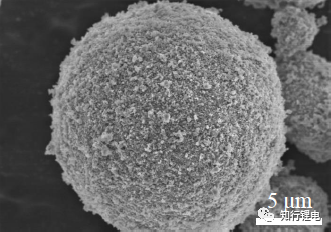

Spherical ternary uncoated safety material, acupuncture pass rate 0%

Spherical ternary coated with 10% iron & manganese based material, the penetration rate of acupuncture is greatly improved

Improvement for "thermal runaway"

A large amount of electrolyte in a burning state is ejected when the cell is thermally out of needle punching. Therefore, if the electrolyte is flame retardant, the thermal runaway of the needle punch may be suppressed.

The flame retardant electrolyte can be divided into two main directions, one is to change the original low flash point linear ester in the solvent to a cyclic ester (it may also need to change the lithium salt), and the other is to add flame retardant additives to the solvent. There are mainly phosphorus, halogen and composite flame retardants.

In addition to using flame-retardant electrolytes, the choice of flame-retardant separators can also improve needle punching. However, since the burning of the separator is not the root cause of needle punching failure, it can only reduce the fire after needle punching thermal runaway. The effect also needs to cooperate with other improvement methods.

Doubts: Why do many materials on the Internet show that the stable temperature of the negative electrode is lower than that of the positive electrode? But this article frequently said that the positive is the key to safety?

When Wenwu searched the reference materials in this article, he also found a lot of data showing that the reaction temperature of the negative electrode and the electrolyte is lower. For example, the following is a high-temperature heat generation diagram of various materials inside the cell that is widely spread:

The thermal shock and acupuncture content of this article use the positive electrode as the key point for improvement, for two reasons:

(1) The experiment proves that the high-temperature stability of the iron-lithium + graphite cell is much higher than that of ternary + graphite, so the negative electrode is indeed not a short plate of high-temperature stability in the conventional system;

(2) If the positive electrode is unstable, it will release oxygen, which is very dangerous for the current liquid electrolyte system. Even if the negative electrode is unstable, it will only generate heat, which is not the same as the dangerous degree of oxygen release.

As for the reaction between the negative electrode and the electrolyte, the actual self-chemical achievements have begun and run through the battery life. It is also normal for the laboratory to test for a lower initial temperature of heat release. Based on the above factors, this paper believes that in many safety tests, the shortcoming of failure lies in the positive electrode rather than the negative electrode.

Acupuncture summary

Failure principle: local high temperature caused by complex internal short circuit

Key improvements: vest structure, positive electrode stability

Possible improvements: high puncture strength and melting point separator, thin and large cell shape, negative electrode finishing structure, flame retardant electrolyte, flame retardant separator

Brainstorm improvement points: Insulation coating of inner shell, hard enough pole piece, improve negative electrode heat dissipation, change the surface material of aluminum foil

3. Heavy impact

Test Conditions

Place a metal rod horizontally on the surface of the cell, the heavy hammer falls from the air and hits the metal rod

Failure principle

The huge impact of the metal rod will smash the battery cell out of the mark or directly break it, which will cause a short circuit in the battery cell.

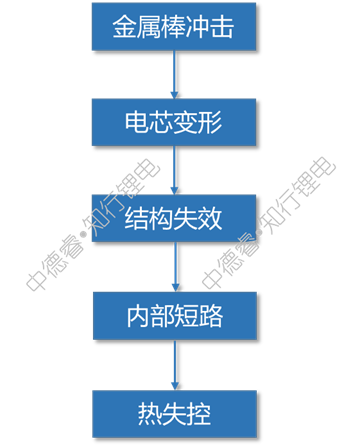

The causal chain diagram describes the failure principle as follows:

Improvement plan

Improvement for "Metal Bar Impact" or "Battery Deformation"

(This is the last time the information has appeared)

Improvement for "cell damage or breakage after heavy impact"

If you can ensure that the battery core is intact after the impact of heavy objects, then the subsequent risks will not exist. This direction is also the main measure to improve the impact of heavy objects:

(1) Influence of cell size: The wider and thicker the cell, the easier it is to absorb the impact energy of the metal rod, while the narrow and thin cell is easy to break as soon as it is smashed, and the risk increases. Of course, if the impact energy is too high, the improvement effect of the cell size is limited.

(2) The influence of the rigidity of the battery core: the battery core is "hard", it is like training an iron cloth shirt with "a gun pierced a point, a knife cut a mark", and it may be unscathed after the impact of a heavy object; the battery core does The "soft" is like a clever break, which can buffer the impact of the metal rod and also improve the effect.

Of course, the degree to which the hardness of a model is the easiest to impact through a heavy object is also closely related to its size. According to Wen Wu’s limited personal experience, a narrow battery core is a little softer (similar to a clever break), and a wide battery core Harder (just keep you smashing) will be better.

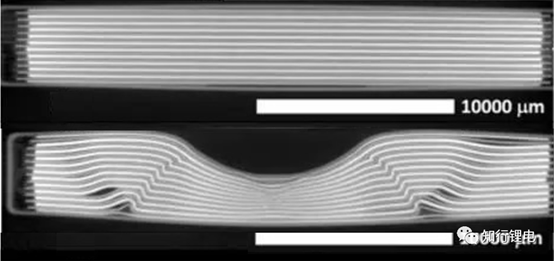

(3) Mechanical strength of the diaphragm: Although the battery core can not be broken when a heavy object strikes, the interior will still be seriously deformed, as shown below:

Before the impact of the heavy object in the picture above, after the impact of the heavy object in the picture below

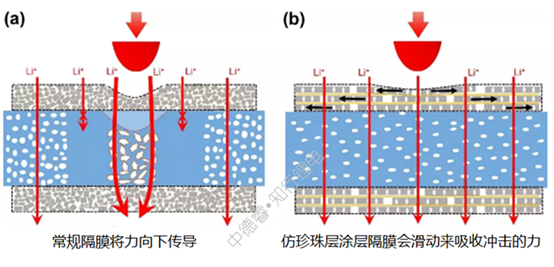

In order to ensure that a large area of internal short circuit does not occur after the impact of a heavy object, the diaphragm also needs to have high mechanical strength and failure strain.

(4) Add cushioning material inside the battery core: for example, a layer of imitation pearl coating can be coated on the surface of the diaphragm. When impacted by a heavy object, the coating will slide between the coatings to reduce the damage of the diaphragm and the structure of the battery core.

Improvement for "short circuit in cell"

After a heavy object damages or breaks the battery cell, the internal short circuit is much lighter than the needle puncture: if the battery cell is not broken, the contact surface between the metal rod and the positive and negative plates is very small; if the battery cell is broken It is also difficult for metal rods to keep in close contact with the positive and negative plates.

The corresponding improvement measures are the same as those above to avoid short circuits in the cell after acupuncture, which are some conceptual solutions and will not be repeated.

Summary of Heavy Impact

Failure principle: the impact of the metal rod causes the internal materials and structure of the battery to fail and causes an internal short circuit

Key improvement points: cell shape, cell hardness

Possible improvements: positive electrode stability, separator mechanical strength

Brainstorm improvement point: increase buffer substance in the battery cell